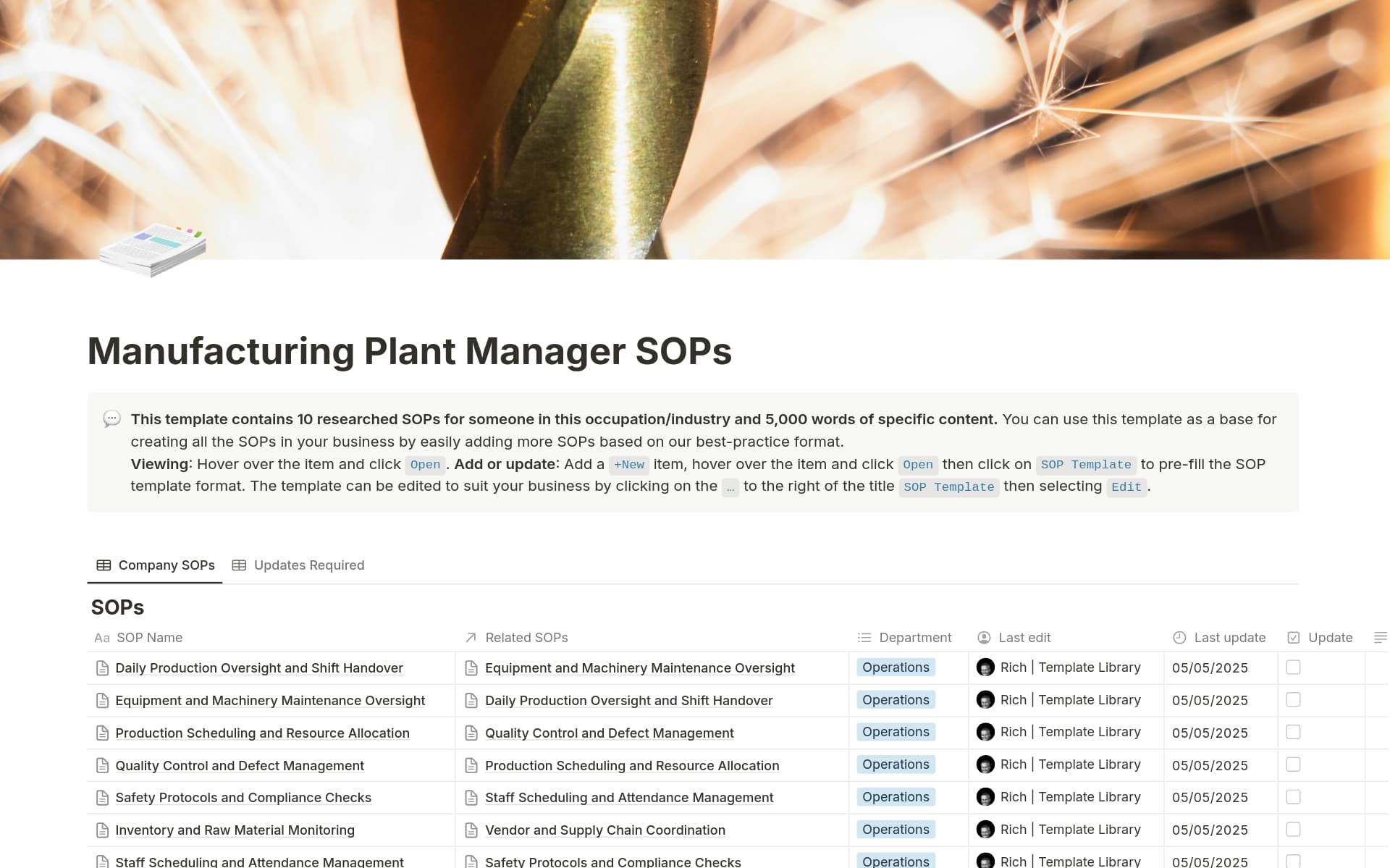

Gas And Oil Servicer SOPs

About this template

This template contains a comprehensive set of Standard Operating Procedures (SOPs) for gas and oil servicing operations. It outlines ten distinct SOPs, each addressing a critical aspect of the industry, ranging from routine maintenance and safety protocols to emergency procedures and inventory management. The document provides detailed steps for conducting routine maintenance on oil and gas equipment, including preparation, safety compliance, inspections, servicing, and testing. It also emphasizes the importance of logging findings and post-maintenance cleanup.

The SOPs also cover safety procedures for hazardous environments, detailing steps for assessing work environments, using personal protective equipment (PPE), following site-specific protocols, and implementing safe work practices. Emergency shutdown procedures are outlined, including recognizing emergency conditions, activating protocols, accessing shutdown controls, and reporting incidents. Additionally, the document provides guidance on testing and monitoring equipment performance, ensuring functionality and identifying potential issues through baseline measurements, functional testing, and data analysis.

Furthermore, the document includes procedures for gas leak detection and response, emphasizing the recognition of leak signs, activation of safety protocols, use of detection equipment, and mitigation strategies. Inventory management of spare parts and tools is addressed, detailing the establishment of an inventory system, tracking incoming inventory, proper storage, and usage monitoring. Coordination with emergency services is covered, outlining protocols for initiating communication, preparing for arrival, supporting operations, and post-emergency coordination.

Incident reporting and analysis are thoroughly discussed, emphasizing the identification of reportable incidents, immediate notification, completion of reports, investigation, and development of corrective actions. Training and certification for hazardous work are outlined, including defining requirements, developing training programs, certifying providers, and conducting assessments. Finally, preventive maintenance scheduling is detailed, covering the establishment of requirements, development of schedules, allocation of resources, execution of tasks, and analysis of maintenance data.

In summary, this document serves as a vital resource for ensuring safety, efficiency, and compliance in gas and oil servicing operations by providing detailed, step-by-step instructions for a wide range of critical procedures.