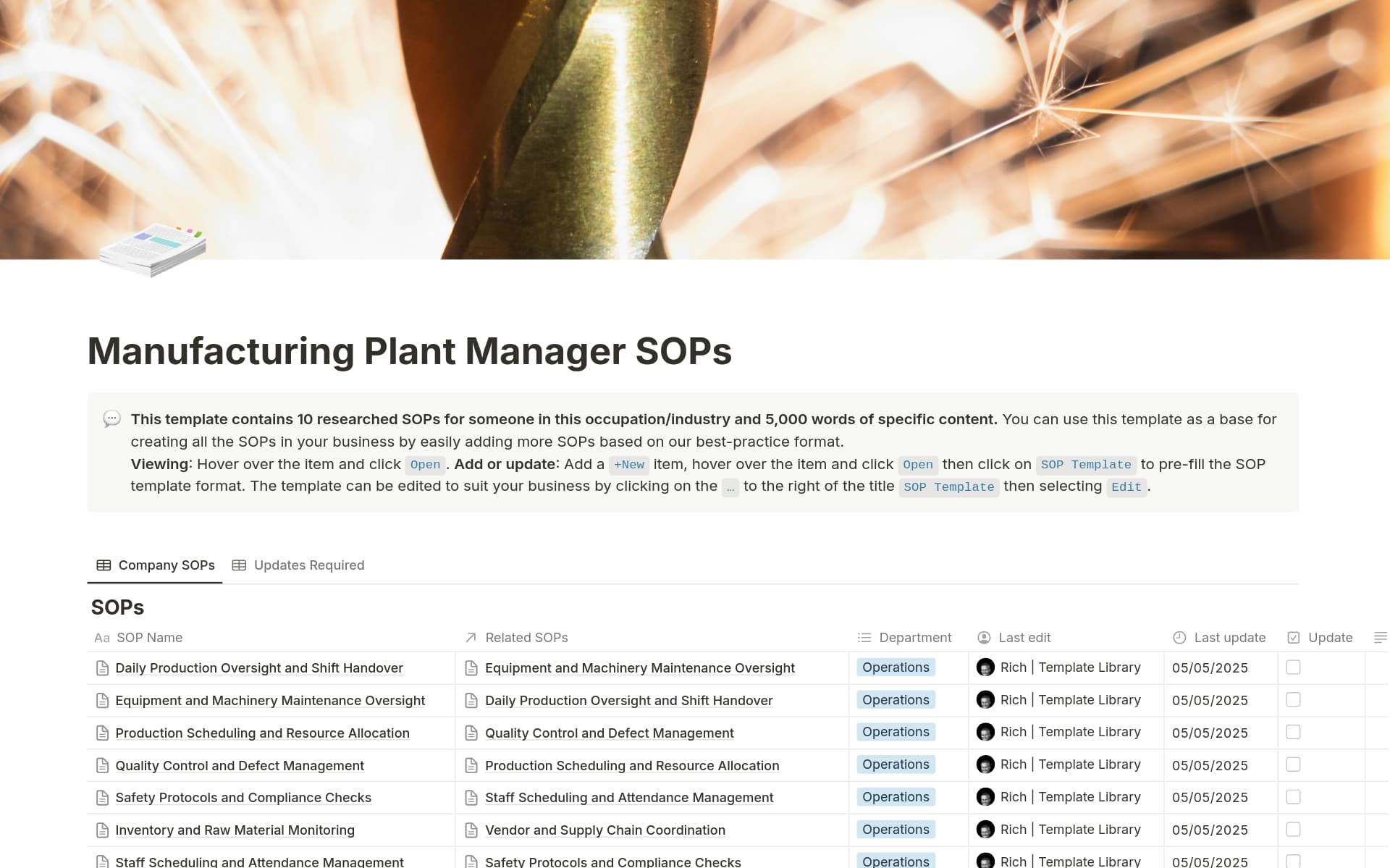

Facilities Maintenance Worker SOPs

About this template

This template contains a set of Standard Operating Procedures (SOPs) designed for a Facilities Maintenance Worker. The document outlines ten distinct SOPs, each focusing on different aspects of facility maintenance, ranging from routine inspections to specialized procedures. These SOPs provide step-by-step instructions to ensure maintenance tasks are performed consistently, safely, and effectively, covering areas such as HVAC systems, electrical systems, plumbing, fire safety, and work order management.

SOP 1 addresses Routine Facility Inspection and Maintenance, detailing preparation, structural and general inspections, HVAC, electrical, and plumbing checks, as well as safety equipment and grounds inspection. It also includes documentation and reporting procedures along with minor repair guidelines. SOP 2 covers Preventive Maintenance of HVAC Systems, outlining preparation, inspections, filter replacement, ductwork checks, coil cleaning, refrigerant levels, blower components, electrical connections, thermostat calibration, and final system checks.

SOP 3 focuses on Electrical System Inspection and Repair, including preparation, inspection of panels, breakers, outlets, wiring, lighting, emergency systems, hazard identification, minor repairs, documentation, and safety checks. SOP 4 deals with Plumbing System Maintenance, detailing pipe and water line inspections, faucet and fixture checks, drain unclogging, water heater servicing, toilet system repairs, pump inspections, hazard identification, minor repairs, documentation, and safety checks. SOP 5 outlines Emergency Equipment Inspection, covering fire extinguishers, smoke detectors, emergency lighting, alarm systems, first aid kits, and sprinkler systems.

The remaining SOPs address specialized procedures. SOP 6 concerns Fire Safety System Testing, covering alarms, detectors, sprinklers, extinguishers, exits, lighting, fire doors, and documentation. SOP 7 details Fire Extinguisher Maintenance and Recharging, including visual inspection, pressure checks, cleaning, testing, recharging, component replacement, tag updates, and proper placement. SOP 8 provides guidance on Fire Drill and Evacuation Procedures, including planning, occupant preparation, activation, evacuation, assembly, scenarios, evaluation, documentation, and corrective actions. Finally, SOPs 9 and 10 cover Lockout/Tagout (LOTO) for Equipment Maintenance and Work Order Management and Documentation, respectively, ensuring safety during servicing and efficient tracking of maintenance tasks.