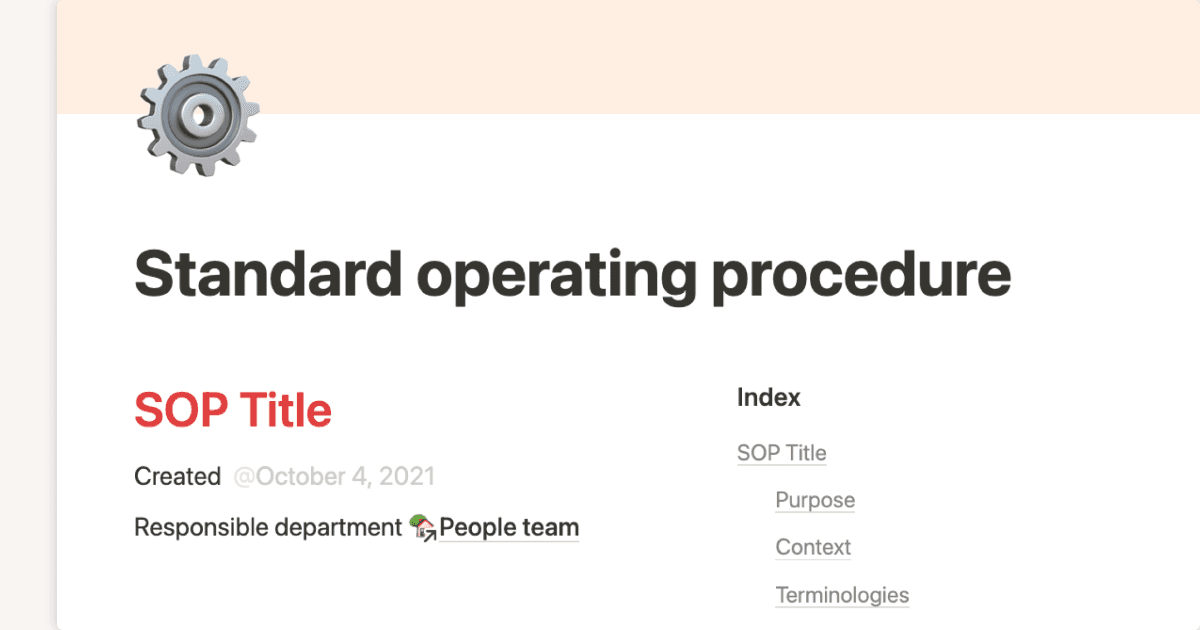

Production Supervisor SOPs

About this template

This template contains Standard Operating Procedures (SOPs) for various aspects of production supervision. It outlines guidelines for daily planning and shift allocation, monitoring and reporting production output, ensuring equipment readiness and safety, and managing downtime and delays. The document also details procedures for conducting pre-shift and post-shift briefings, workforce management, quality control, and inventory management. Additionally, it provides instructions for preventing material wastage and loss, as well as implementing continuous improvement and lean practices.

The SOPs emphasize the importance of thorough preparation and planning before each shift. This includes reviewing production schedules, checking resource availability, allocating tasks to team members, and conducting pre-shift meetings to communicate goals and expectations. Supervisors are instructed to monitor production progress throughout the shift, track key performance metrics, and address any variances or delays promptly. Ensuring equipment readiness and safety is also a critical component, with detailed steps for pre-shift inspections, emergency system tests, and ongoing maintenance.

Quality control and defect management are covered extensively, with guidelines for in-process monitoring, root cause analysis, and corrective actions. The document stresses the importance of maintaining accurate inventory records, preventing material waste, and implementing first-in, first-out (FIFO) practices. Workforce management is another key focus, with procedures for attendance tracking, task allocation, performance monitoring, and on-the-job coaching. Supervisors are advised to address conflicts professionally and provide regular feedback to their team.

To foster a culture of continuous improvement, the SOPs recommend implementing lean practices such as 5S workplace organization, value stream mapping, and standardized work. Kaizen events are encouraged to address specific production problems, and ongoing employee training and skill development are highlighted. Performance measurement and feedback are crucial for tracking progress and sustaining improvements, with regular reviews and reporting to management.

Overall, this document provides a comprehensive framework for production supervisors to manage daily operations effectively. By following these SOPs, supervisors can ensure smooth production, minimize waste, improve quality, and foster a productive and safe work environment. The detailed guidelines and documentation requirements promote accountability and facilitate ongoing process optimization.