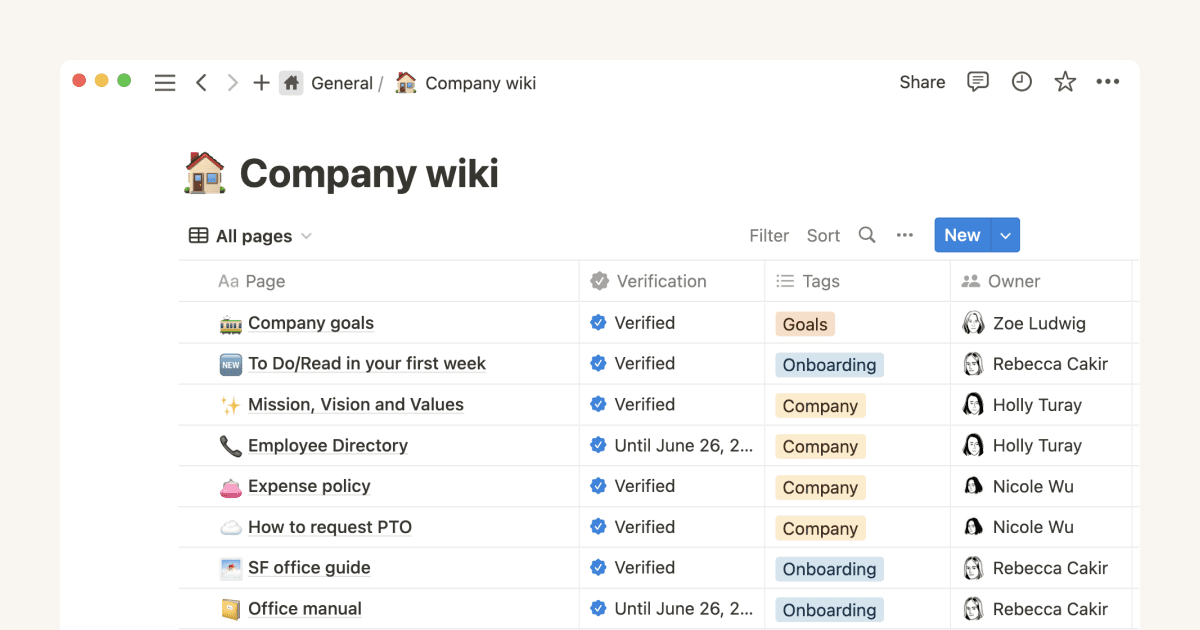

Plant Maintenance Mechanic SOPs

About this template

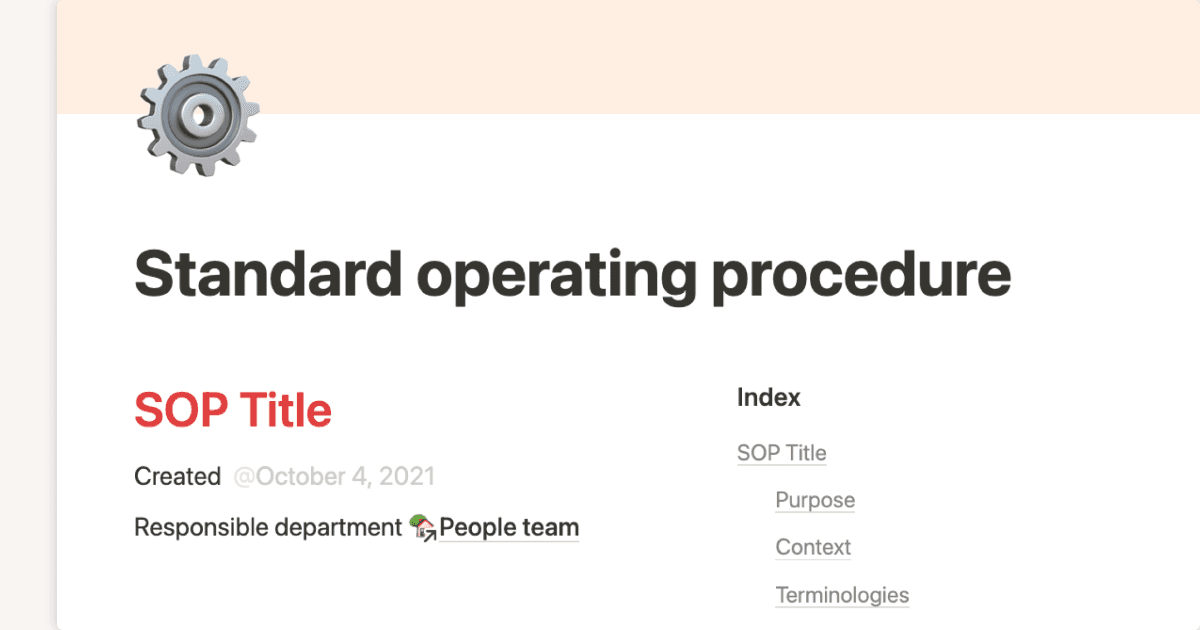

"This template contains Standard Operating Procedures (SOPs) for Plant Maintenance Mechanics. These SOPs cover a wide range of tasks to ensure the safe and efficient operation of plant equipment and machinery.

The first SOP focuses on routine preventive maintenance to keep equipment running smoothly and safely. This includes reviewing maintenance schedules, following safety procedures, inspecting equipment, and performing necessary cleaning, lubrication, adjustments, and tests. Proper documentation is essential throughout the process.

The second SOP is about troubleshooting mechanical failures. Mechanics must identify the issue, follow safety checks, inspect the equipment, and use diagnostic tools to isolate the root cause. Repairs or component replacements may be needed, followed by reassembly and testing. Findings must be documented and communicated.

Another SOP guides mechanics on lubricating and adjusting machinery. This involves reviewing maintenance requirements, gathering tools and materials, and following safety procedures. Lubrication points must be cleaned before applying the correct lubricant. Components may also need inspection and adjustment, followed by machinery testing and documentation.

The document also includes an SOP for inspecting safety systems and protocols. This is crucial to protect workers and equipment from hazards. Mechanics are responsible for reviewing safety requirements, preparing for inspections, and checking various safety systems and emergency protocols. Any required maintenance or repairs must be performed, followed by system testing and documentation.

Other SOPs cover tasks such as repairing hydraulic and pneumatic systems, responding to emergency equipment failures, installing new equipment, managing spare parts inventory, calibrating equipment and instrumentation, and conducting end-of-shift reporting. Each SOP outlines the purpose, scope, reference SOPs, and step-by-step procedures to ensure tasks are performed consistently and effectively. "