More by SOPs

More like this

Related content

For Teams

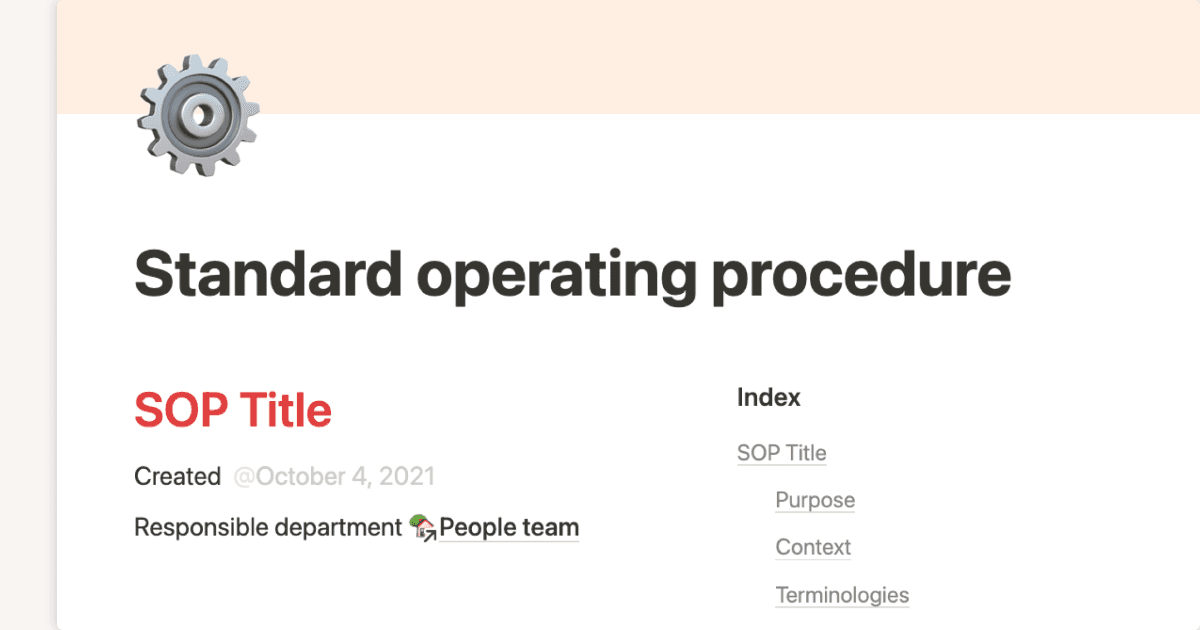

The SOP template your startup needs

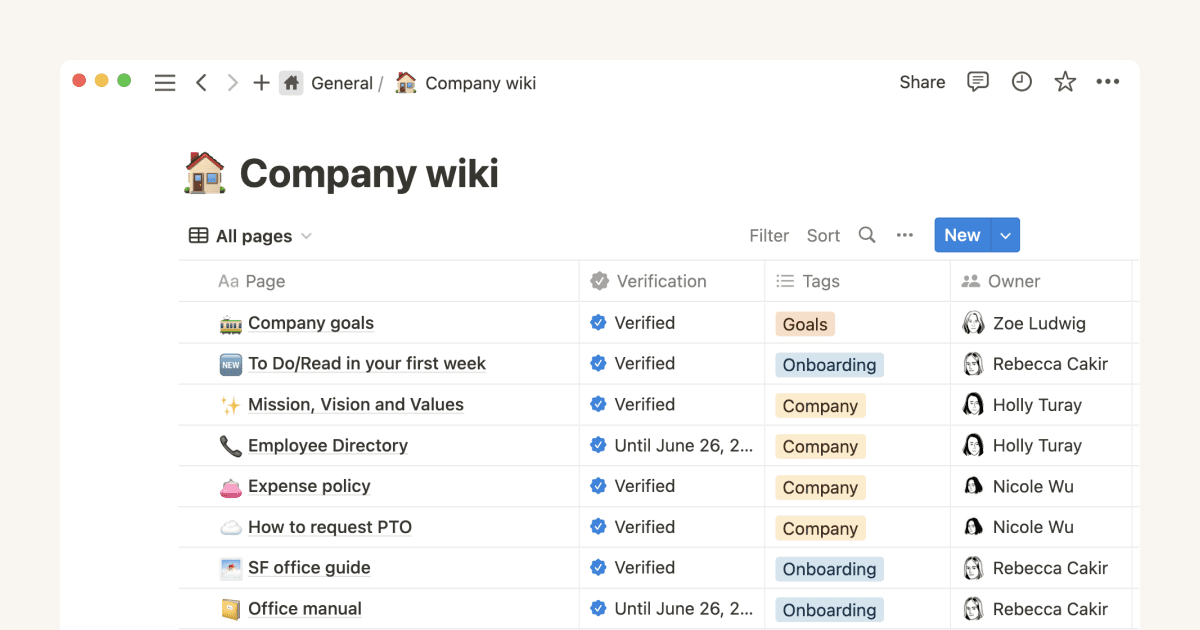

Standard operating procedures (SOPs) don’t have to be painful to maintain or systematize. Having an SOP template in place will set your startup up for success. With an SOP template to start with, standard guidelines, and rigorous taxonomy, SOPs can become the resource they’re intended to be instead of a pain.

Nate Martins

Marketing