Industrial Conveyor Belt Repairer SOPs

About this template

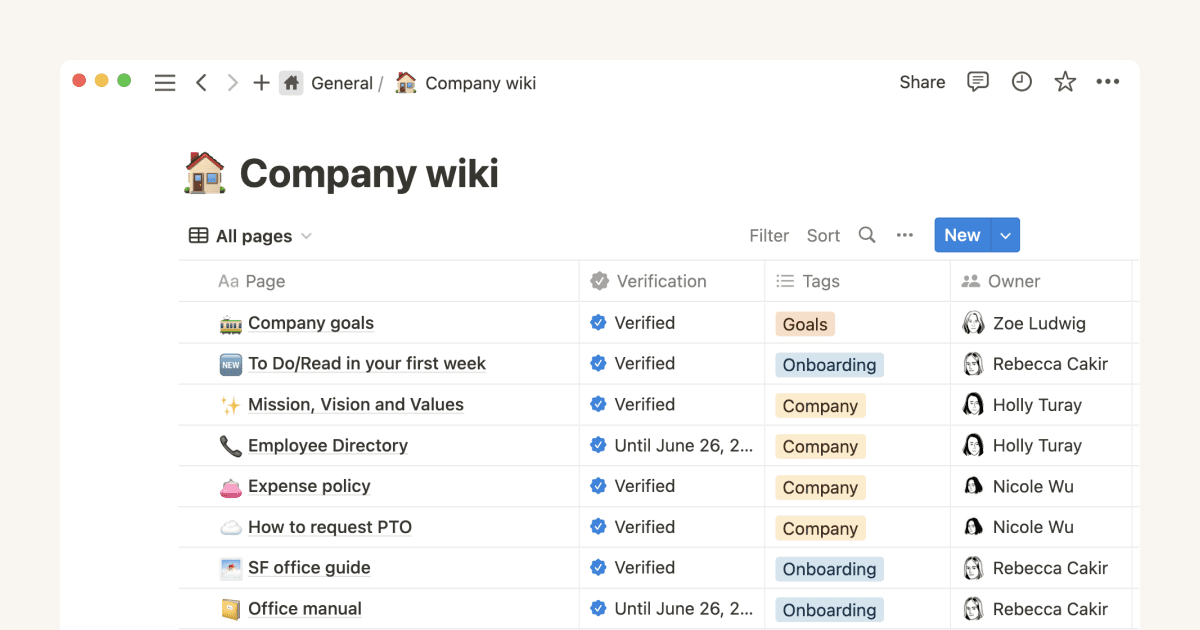

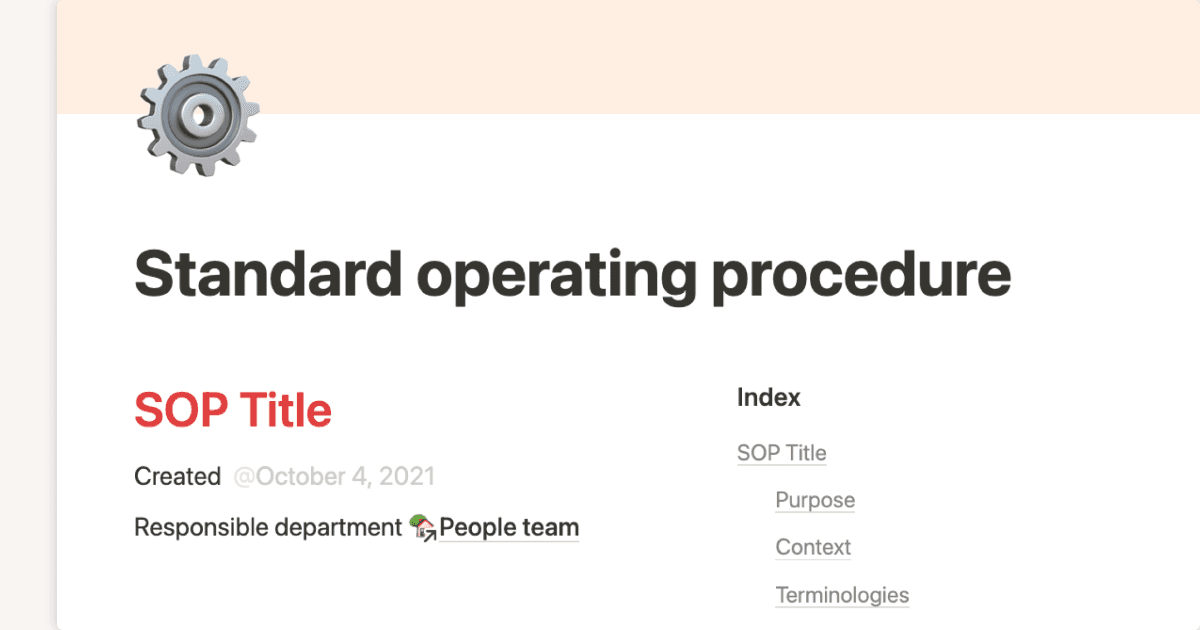

This template contains Standard Operating Procedures (SOPs) for industrial conveyor belt repairers. It covers a wide range of essential tasks, including inspecting belts for damage, cleaning and preparing belts for repair, identifying and replacing worn components, and handling emergency belt repairs. The document also details procedures for splicing conveyor belts, adjusting tension and tracking, replacing belt sections, lubricating components, performing preventive maintenance, and troubleshooting common issues. Each SOP outlines the purpose, scope, and detailed steps required to complete each task safely and effectively.

The first SOP focuses on inspecting conveyor belts for damage. It emphasizes the importance of early detection of wear and tear to prevent costly downtime. The procedure includes preparing for inspection by gathering tools and reviewing maintenance history, conducting a visual inspection, assessing structural and mechanical components, performing specialized tests, and documenting findings. It also covers post-inspection cleanup and communication of critical issues.

The second SOP details the cleaning and preparation of conveyor belts before repair. This involves preparing the workspace, assessing cleaning requirements, performing initial and thorough cleaning, applying appropriate cleaning agents, and inspecting the belt. It also includes steps for disposing of waste materials, communicating completion, and documenting the process for future reference.

Further SOPs guide technicians through identifying and replacing worn components, handling emergency belt repair protocols, and splicing conveyor belts. These procedures ensure that repairs are conducted efficiently and effectively, minimizing disruptions to operations. The document also provides instructions for adjusting belt tension and tracking, which are crucial for maintaining the smooth and efficient operation of conveyor systems.

Finally, the template covers preventive maintenance and troubleshooting. These SOPs aim to ensure long-term reliability and efficiency by outlining systematic approaches to inspections, adjustments, and component care. The troubleshooting SOP provides a step-by-step guide for identifying and resolving common conveyor belt issues, emphasizing safety, documentation, and follow-up actions.