Paper Mill SOPs

About this template

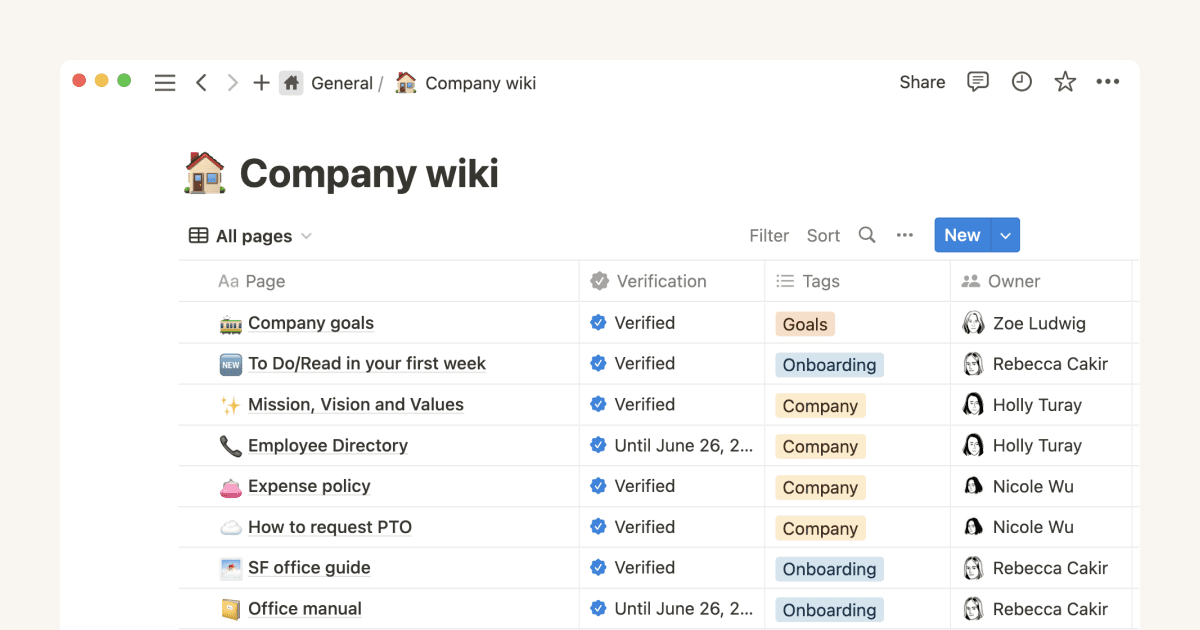

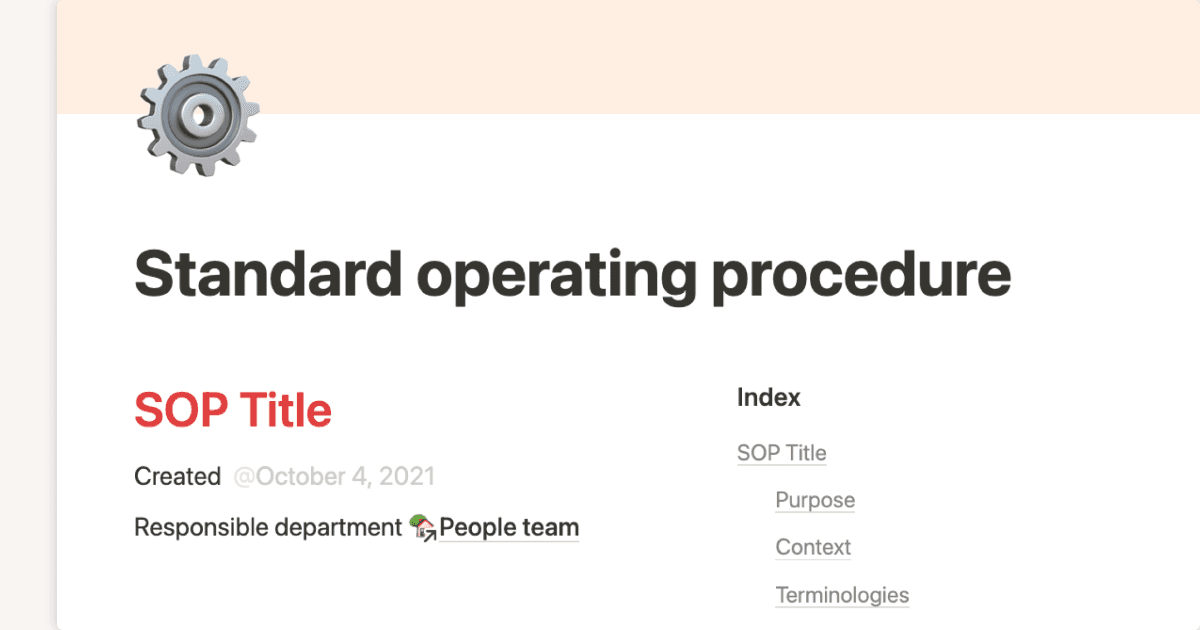

This template contains Standard Operating Procedures (SOPs) for a paper mill, detailing processes from raw material procurement to waste management. SOP 1 outlines the steps for acquiring and storing raw materials, emphasizing vendor selection, quality inspection, and inventory management. SOP 2 focuses on equipment maintenance and calibration, advocating for regular schedules, pre-operation inspections, and emergency repair protocols. SOP 3 describes the production line operations, including preparation, initiation, quality maintenance, and end-of-shift protocols.

The document further includes SOP 4, which details quality control and testing procedures for raw materials, in-process products, and finished goods, ensuring adherence to quality standards and regulatory compliance. SOP 5 establishes safety procedures and emergency response plans to mitigate risks and ensure the well-being of all personnel. SOP 6 outlines the handling and packaging of finished products, focusing on inspection, packaging material selection, and proper labeling.

Additionally, the template provides SOP 7, which covers warehouse management and logistics, emphasizing efficient organization, storage conditions, and inventory management practices. SOP 8 details inventory management, including classification, system implementation, setting stock levels, and conducting regular audits to optimize stock turnover and minimize losses. SOP 9 focuses on hazardous material handling, stressing the importance of identification, training, safe storage, and emergency response to spills or leaks.

Lastly, SOP 10 describes waste management and recycling, advocating for waste segregation, handling recyclable materials, safe storage, and proper disposal of non-recyclable waste. The document emphasizes continuous improvement across all SOPs through feedback mechanisms, technology upgrades, and regular reviews. It also includes important related aspects like wastewater monitoring, waste audits, and staff training.

In conclusion, this comprehensive set of SOPs aims to standardize operations, ensure safety, maintain quality, and promote environmental responsibility within the paper mill. The procedures cover every aspect of the mill's functioning, from the initial procurement of materials to the final dispatch of finished goods, with a strong focus on efficiency, compliance, and sustainability.