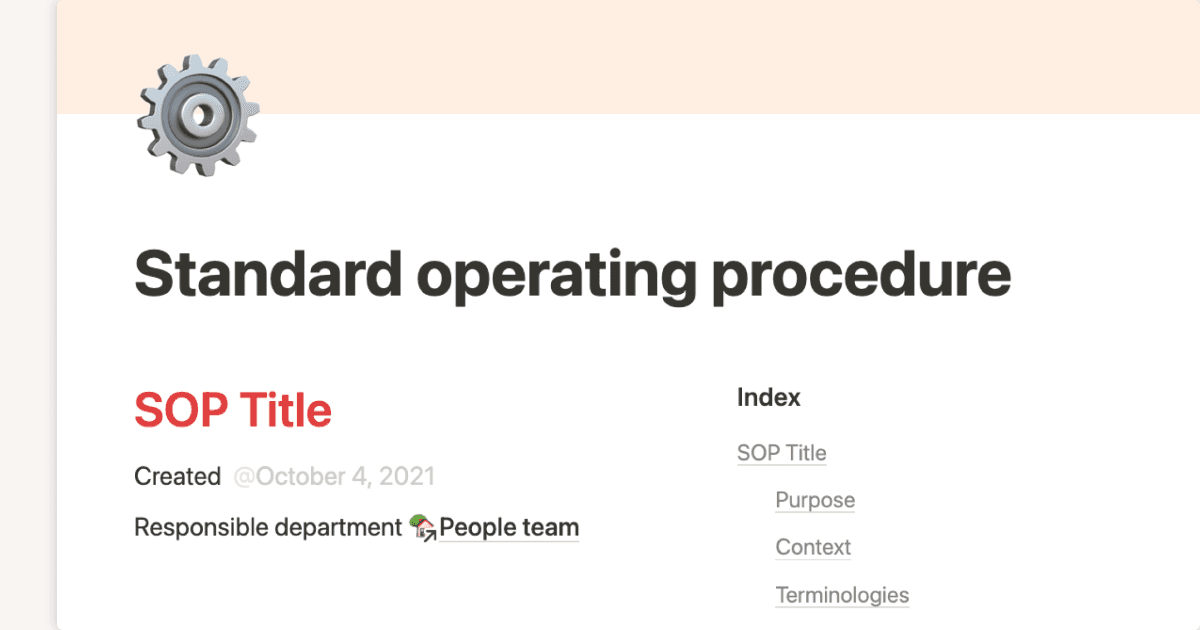

Inventory Manager SOPs

About this template

This template contains a series of Standard Operating Procedures (SOPs) designed for managing inventory within a warehouse or similar facility. The SOPs cover a wide range of inventory-related activities, including receiving and inspecting new stock, organizing and storing inventory, performing stock reconciliation and cycle counting, and handling damaged or expired goods. They also address supplier returns, discrepancy resolution, picking and order fulfillment, investigating and resolving discrepancies, dispatch and shipping, returns and restocking, and inventory performance reporting.

The first SOP details the inventory receiving and inspection process, which ensures accuracy, quality checks, and proper recording of incoming stock. It outlines steps for preparation, verification against documentation, physical inspection, recording and labeling, stock placement, handling discrepancies, and final documentation. The second SOP focuses on inventory storage and organization, emphasizing efficient and systematic storage to prevent misplacement and stock deterioration. It includes guidelines for storage area classification, inventory placement, storage conditions, security, and updating the Inventory Management System (IMS).

The third SOP describes stock reconciliation and cycle counting, processes that ensure physical inventory counts match recorded stock levels in the IMS/ERP. It covers full physical counts, cycle counting, ABC analysis counting, and steps for investigating and resolving discrepancies. The fourth SOP provides procedures for handling damaged or expired inventory, including identification, segregation, assessment, returns, disposal, and record updates. It aims to prevent accidental use, contamination, or financial loss from unusable stock.

The fifth SOP outlines the process for supplier returns and discrepancy resolution, ensuring that incorrect, damaged, or defective inventory is promptly returned. It details steps for identifying discrepancies, quarantining stock, notifying suppliers, coordinating returns, updating records, and resolving disputes. The remaining SOPs cover order fulfillment, discrepancy investigations, dispatch and shipping, returns processing, and performance reporting, all aimed at optimizing inventory management and minimizing errors and losses.