Design Engineer SOPs

About this template

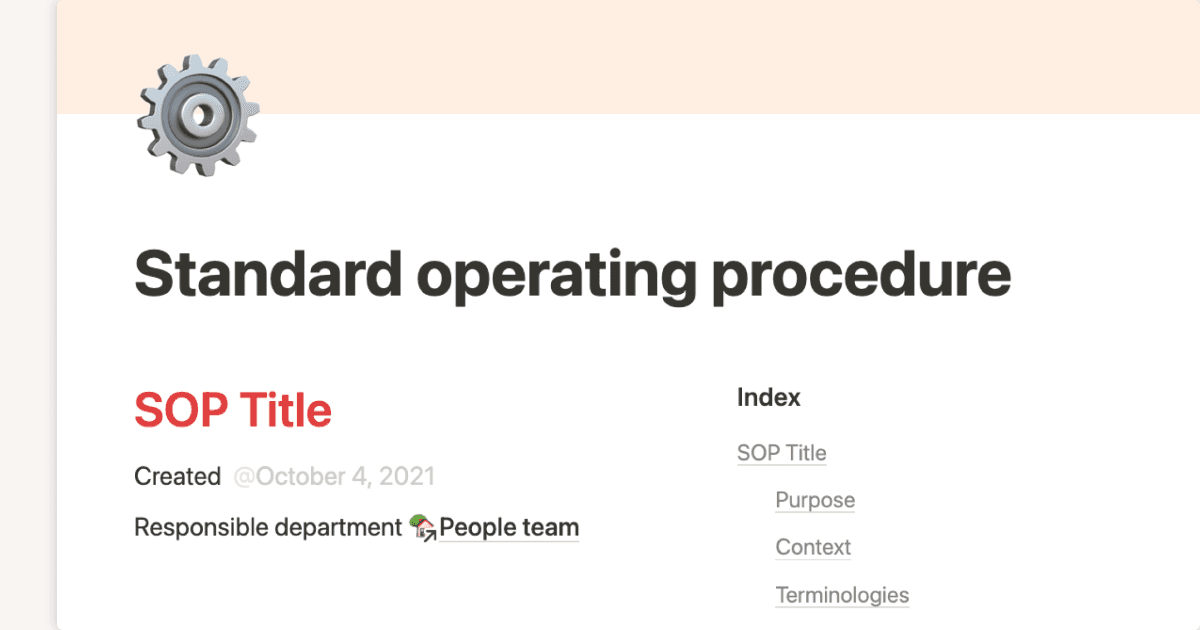

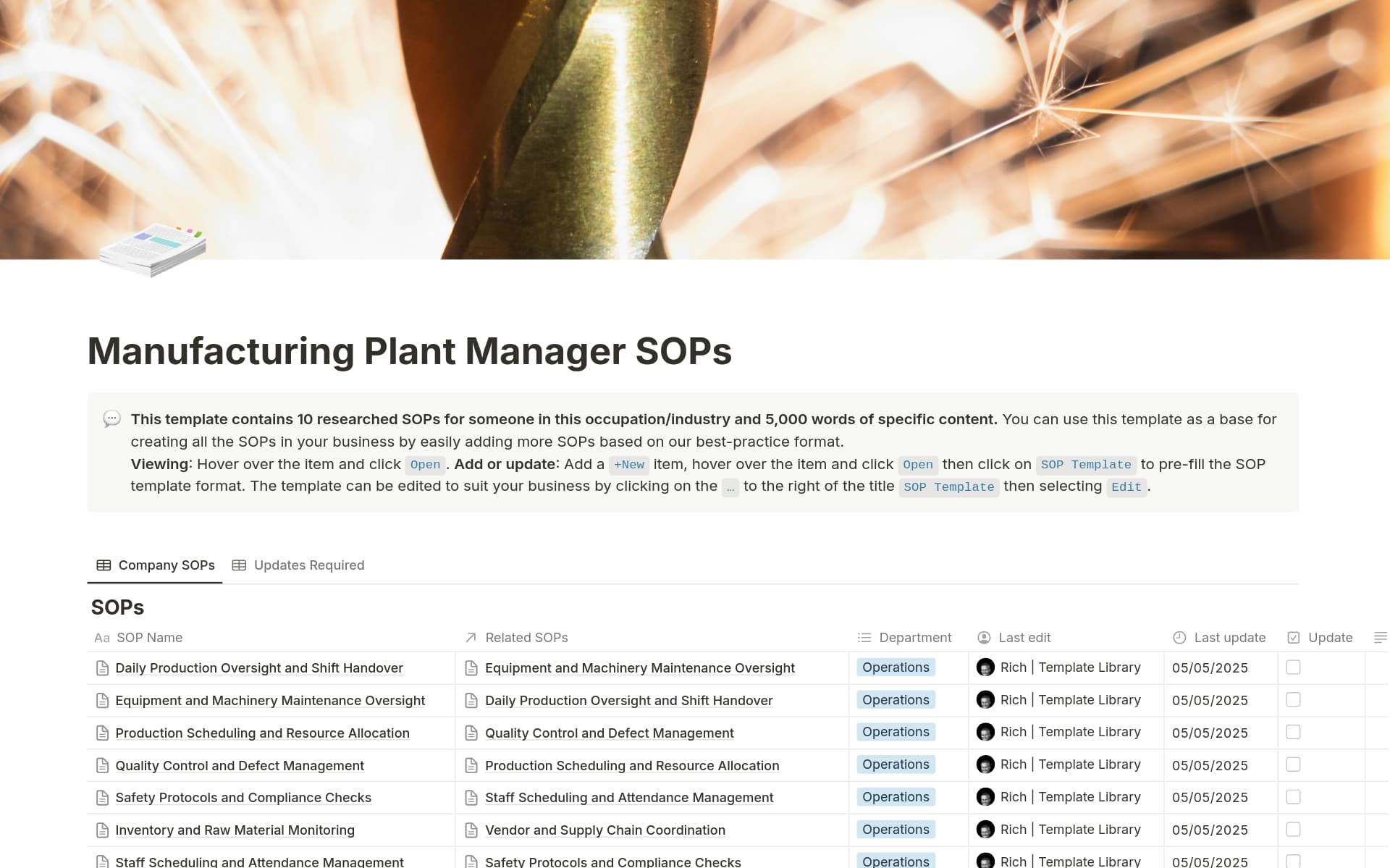

This template contains a comprehensive set of Standard Operating Procedures (SOPs) for Design Engineers. These SOPs cover a wide range of essential processes, including creating and managing engineering drawings, conducting design reviews, implementing version control, adhering to CAD software best practices, and managing engineering changes. They also detail material selection, tolerance application, Bill of Materials (BOM) management, supplier collaboration, and prototype development.

The first SOP focuses on the creation and management of engineering drawings, emphasizing understanding design requirements, selecting appropriate CAD software, and ensuring compliance with industry standards. The second SOP outlines the design review and approval process, detailing steps for self-review, stakeholder feedback, and final sign-off. The third SOP covers version control and drawing management, including establishing numbering systems, organizing files, and utilizing Product Data Management (PDM) systems.

Subsequent SOPs delve into CAD software best practices, engineering change management, material selection, and the application of tolerances and GD&T. The SOP on CAD best practices provides guidelines for software setup, file organization, and efficient modeling techniques. The engineering change management SOP defines the process for handling design modifications, ensuring all changes are tracked and approved. The material selection SOP outlines how to choose appropriate materials based on performance, cost, and manufacturability, while the tolerance and GD&T SOP details how to apply precise dimensional controls to ensure parts meet functional requirements.

The final SOPs address BOM creation, supplier collaboration, and prototype development. The BOM SOP provides instructions for creating and managing accurate part lists, essential for procurement and manufacturing. The supplier collaboration SOP emphasizes clear communication, design for manufacturability reviews, and sample approvals to ensure successful production. Lastly, the prototype development SOP outlines the steps for creating and testing prototypes to validate designs before full-scale production.

Overall, these SOPs provide a robust framework for Design Engineers to follow, ensuring consistency, accuracy, and efficiency throughout the design and production process. They cover every stage of product development, from initial concept to final production, aiming to minimize errors, reduce costs, and improve product quality.

round.png&w=96&q=80)